1. Experience sharing

2. Efficiency increase

3. Knowledge

AIA Engineering, a certified ISO 9001 company, specialises in the design, development, manufacture, installation and servicing of high chromium wear, corrosion and abrasion resistant castings used in the cement, mining and thermal power generation industries.

Vega Industries is a wholly owned subsidiary of AIA Engineering, exclusively supplying its products, providing customer support and technical services to customers from its offices worldwide. Please click here to find the office in your region.

Our philosophy is to provide customers with optimized solutions through technical evaluation of their requirements, thereby providing specifically designed solutions in ideal metallurgy for the application, plus offering process optimization services worldwide.

As a result of this approach, the Group is today the leading company for Quality, Services and Innovation in its field with an enviable reputation providing Global Solutions.

A truly global solution to your local requirements

AIA Engineering and Vega Industries have become one of the most successful companies in supplying and installing wear components because they really understand how grinding and crushing operations need to work. This expertise is available to customers worldwide and includes the following:

For more information please contact our group’s regional representative

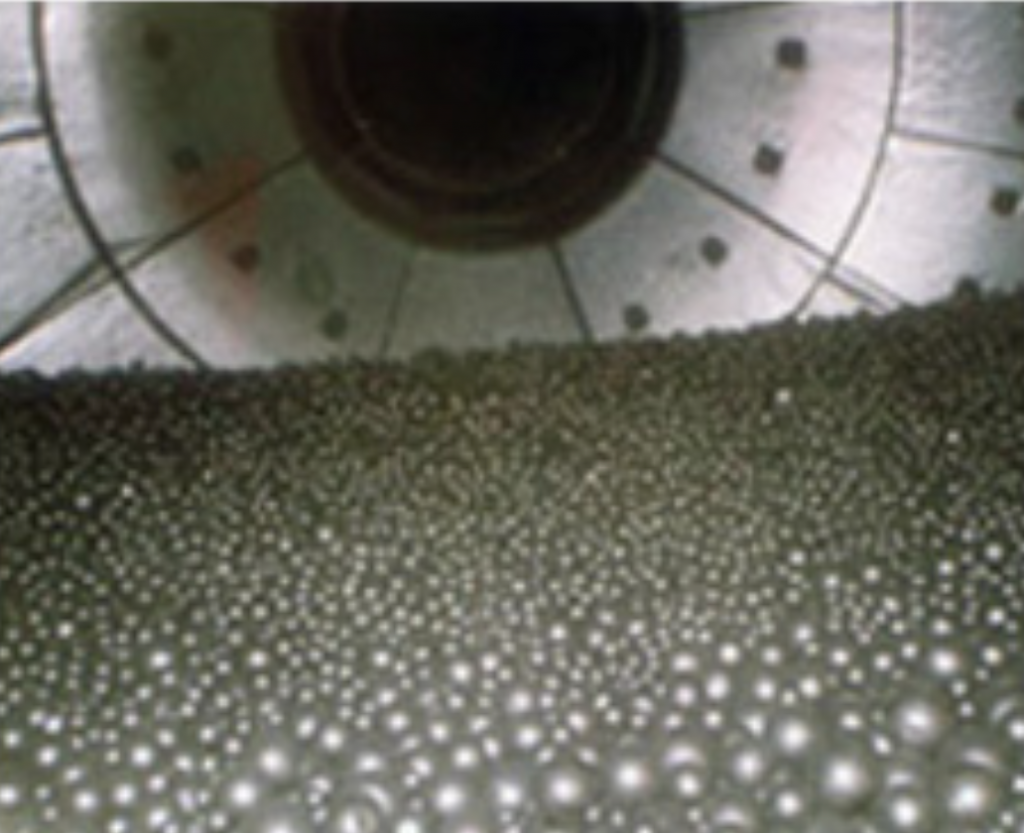

Reduced downtime is critical to successful mining operations, so wear components that work harder and last longer are essential. The Group Industries has developed new alloys and manufacturing techniques that provide improved wear components for all types of minerals including iron, gold, lead/zinc, bauxite, copper and phosphates, etc.

Grinding media and shell liners for mining applications

See our specifications page for grinding media for mining applications. We recognise that requirements can vary from mine to mine, so for more information on how The Group Industries can use its expertise to improve profitability, contact your regional representative.

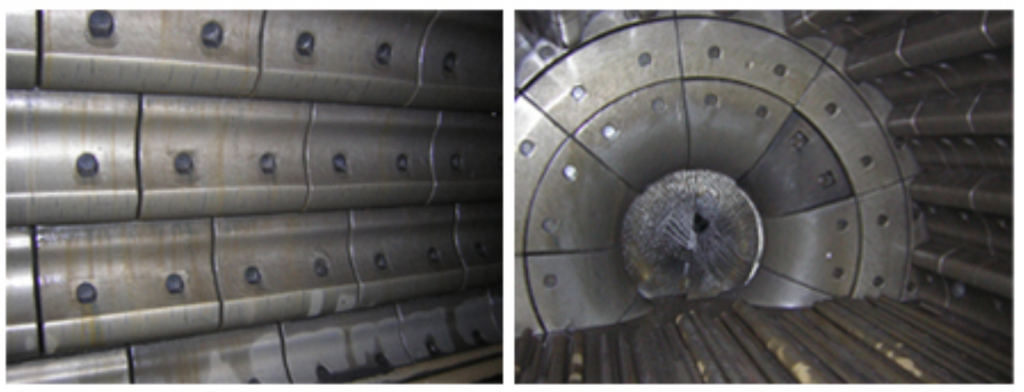

In addition to grinding media, The Group also provides shell liners for ball mills. These are selected according to the relevant stages, that is, single stage, primary, secondary, regrind etc.

Please contact your regional representative to discuss your requirements.

In mineral processing Industry, we deal with various natural ores: | ||

|

|

|

There is no standard solution for mineral industry and wear rate of grinding media varies from mine to mine, ore to ore and even for the same ore time to time.

Different alloys are recommended depending on ore type and mill particulars in order to arrive at the most cost economic solution. Based on our world wide experience, AIAE can help select optimum alloy for specific application ranging from Chromium 10 to 32 % and Hardness ranging from 58 to 69 RC.

Technical Services:

AIAE Solution

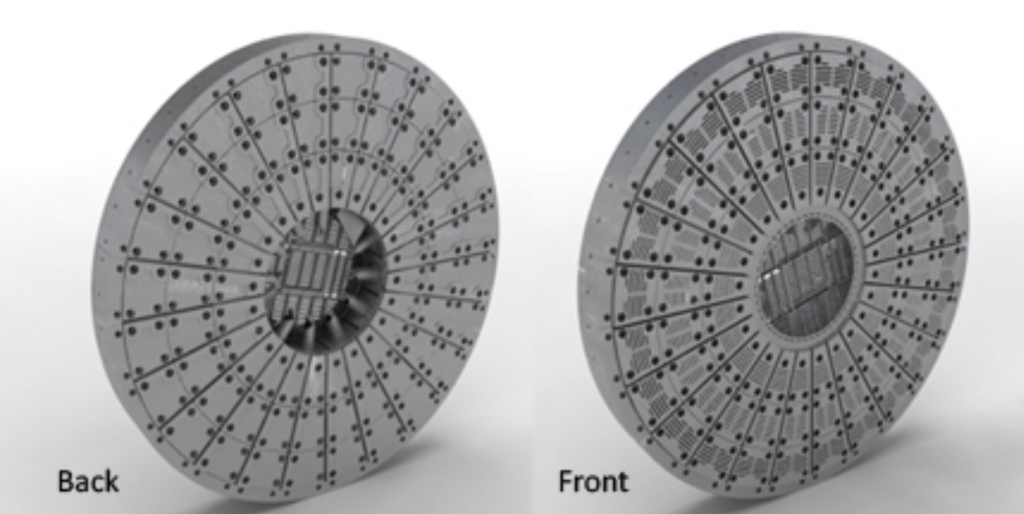

AIAE head liners are tailor made for specific applications keeping in mind maximum mill availability and minimum maintenance cost.

Advantages of AIAE Head Liners:

Note: Depending upon various application, we propose suitable alloys ranging from 10 to 27% Chromium and hardness ranging from 52 to 66 RC.

Mill liners influences:

Based on study of the existing mill operating conditions from maintenance and process point of view, AIAE designs mining liners for ball mills of different stage. i.e. single stage, primary, secondary, regrind etc.

Note : Depending upon the various application, we propose suitable profile with appropriate alloy ranging from 10 to 27 % Chromium and hardness ranging from 48 to 61 RC.

To see how The Group Industries’ liners could improve your efficiency and for a free copy of the product specifications and applications, please contact your regional representative. For information on other cost-saving products from The Group please return to our Mining Industries page.

Improved grinding media and liners can do much for productivity but the benefits can reduce without equally efficient diaphragms. Vega Industries, in co-operation with parent company AIA Engineering, has developed intermediate, discharge, drying chamber and dopple rotator diaphragms that offer maximum useful working life.

This has been achieved with careful design of the slotted and blind wear plates, the use of specially-formulated alloys to suit different conditions and component manufacturing techniques that produce higher quality components.

In addition to longer working life, the wear rates of The Groups diaphragms are synchronised as nearly as possible to that of the liners and grinding media, helping to further reduce the downtime needed for maintenance.

To find out more about The Groups diaphragms for tube mills, please contact your regional representative. If you would like to know more about the other cost-efficient products now available from the company, please return to the Cement Industries page.

Different profile with hump and without hump is available depending on wear and drilling pattern

Note : Depending upon the various application, we propose suitable profile with appropriate alloy ranging from 16 to 27 % Chromium and Hardness ranging from 53 to 61 RC.